CRAFTED PARQUET FLOORING FROM ROTT AM INN

Here at HAIN, we believe in combining modern technology, our many years of experience and high-quality design. The technology creates the conditions – our know-how brings the quality. In our factory in the Bavarian town of Rott am Inn, modern production facilities meet experienced and trained employees. The result: high-quality craft ed parquet flooring that brings a touch of nature into your home. Our self-developed, gentle process brings the best out of the naturally grown wood in our planks and parquet variants. Our pioneering role can be seen, for example, in our special surface structures and our many oxygen-hardened oiled surfaces. However, our natural wood drying process, which gives the planks the time they need to mature, also speaks for the innovative strength of our traditional company. As a company that acts responsibly and has deep roots in our region, we feel equally committed to our customers, our employees and our environment. This is why the raw material wood that we process comes exclusively from sustainably cultivated forests. This way, we produce tough and exclusive craft ed natural floors with lasting quality.

OUR PRODUCT: HIGH-QUALITY PARQUET FLOORING

Oiled natural flooring has an irresistible quality: They become more elegant and beautiful from year to year – a big plus for sustainability! But it’s not only the look that counts: The technical features of HAIN natural flooring are also competitive. A special process of natural wood drying brings out the qualities of the wood to their best advantage. Thanks to our complex and gentle finishing processes, the floors are long-lasting and durable – in almost all areas of application. Each HAIN plank is oiled and oxidatively dried several times – this makes the floor particularly stable and acentuates the natural look of the wood. The naturally finished wood automatically compensates for fluctuations in temperature and humidity, thus having a positive effect on the room climate. Special soap and care balm specially adapted tot he floor ensure easy maintenance.

Product advantages

The high-quality, triple-layered construction with vertical growth rings guarantees the high dimensional stability and durability of the planks. The wear layer, which is up to 4 mm thick, is connected to the spruce substructure using a special press. Different installation heights are available (12 mm, 15 mm and 17 mm) – planks with a thickness of 12 mm are firmly bonded and are ideal for renovations and commercial areas. Thanks to the stable tongue and groove connection, planks with a thickness of 15 mm or more can either be bonded permanently in place or laid in a floating installation, if necessary. The surface can be sanded down multiple times.

- 1. Wear layer:

- up to 4 mm thick made of European wood

- 2. Core:

- Hand-picked core layer made of specially dried, solid spruce planks with vertical growth rings for additional stabilisation of the overall construction

- 3. Backing:

- Backing made of high-quality softwood veneer

Special oil surface

The natural oil finish perfects every single plank and gives HAIN flooring its distinctive character. Before oiling, the wood is gently heated, opening up the pores so that the oil is more effectively absorbed. HAIN’s natural oil (free from coatings or waxy substances) is applied lightly and evenly to the wood. The planks are then placed in special drying racks and given plenty of time for the oil to absorb and air dry. Meanwhile, the wood retains its natural beauty and breathability.

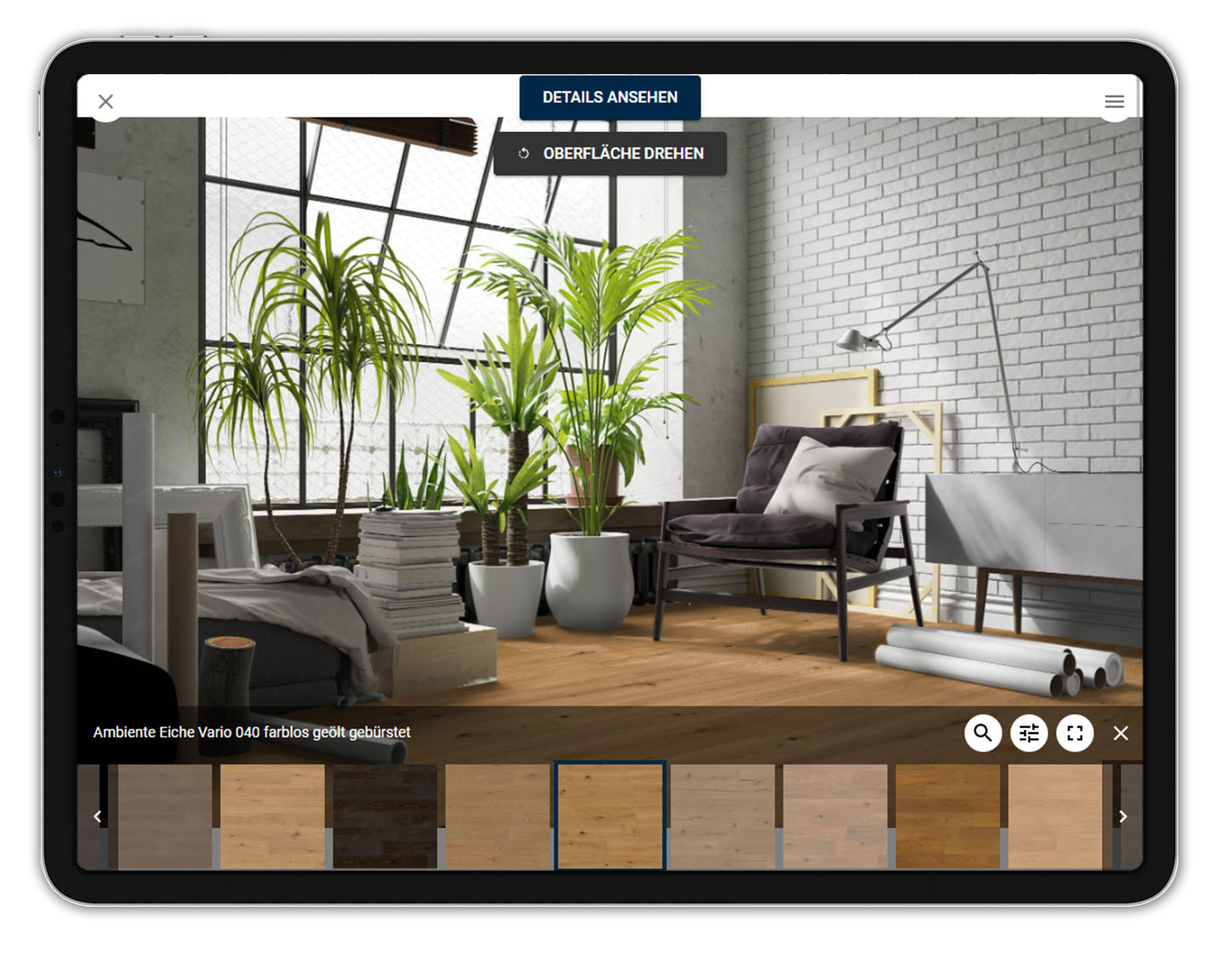

HAIN Room designer

The decision for a new flooring is often not that easy. With the new room designer from HAIN, it is now a little easier. Simply visualise a selection from the HAIN parquet range in your own room.

IT’S THAT SIMPLE:

1. Open the room desginer

2. Use the camera icon to upload a photo of your own room

3. Select a HAIN parquet flooring

4. Adjust it according to your requirements: e.g. change the laying direction.